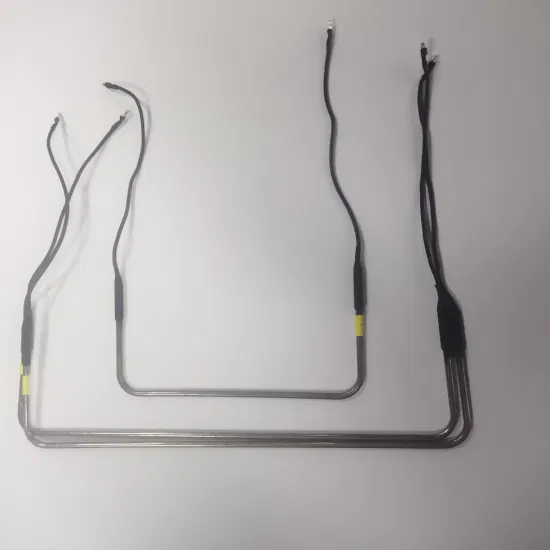

Forged Hexagon Copper Brass Water Heating Element Flange for Heater

FAQ 1), Q: How can I get a sample?A: Yes, if customer want, we will express couple pcs samples free for customer to chec

Description

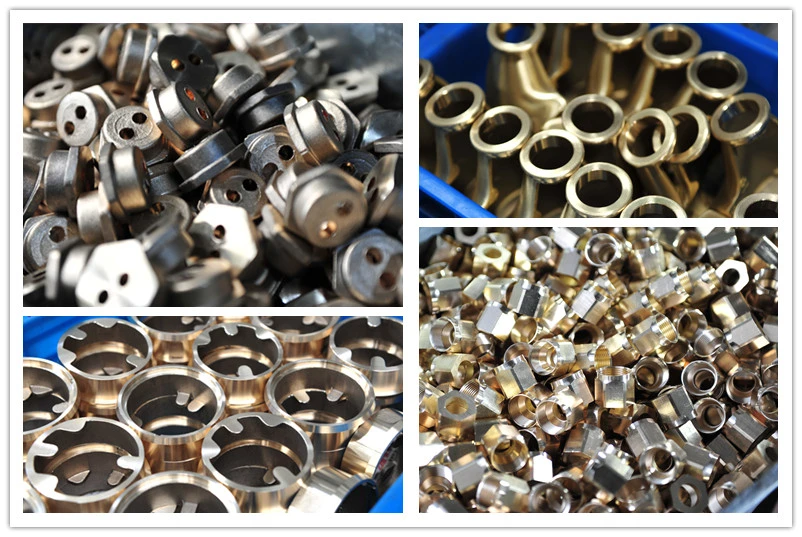

Basic Info.

| Structure | Flanges |

| Connection | Screws |

| Sealing Surface | Thread |

| Manufacturing Way | Forging |

| Voltage | 220-240V |

| Hole | 2,3,4,5,6 |

| Surface Treatment | Sandblasting |

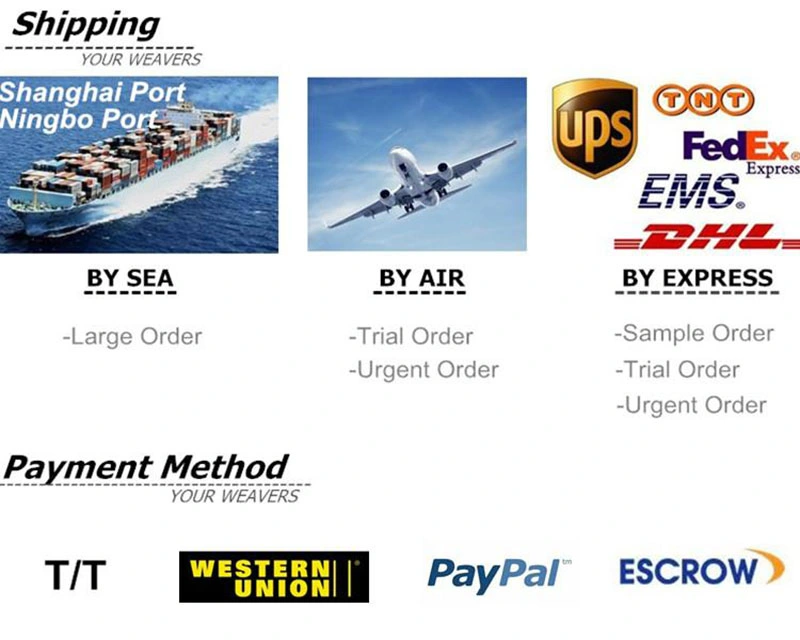

| Transport Package | Carton and Pallet |

| Specification | 2 1/4” BSP*HD9mm, S85*H25mm,M4&M5 4-φ8 |

| Trademark | OEM |

| Origin | Ningbo China |

| Production Capacity | 30000PCS/Month |

Product Description

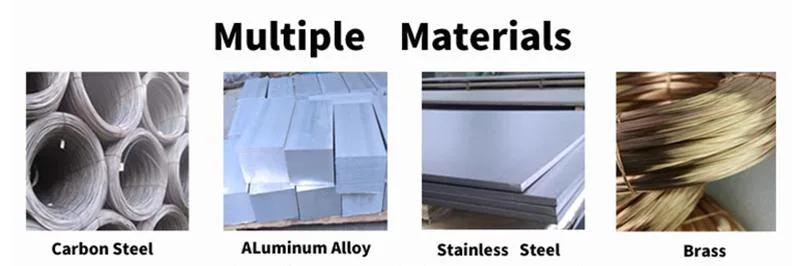

| Material | Brass,Copper,Stainless steel,Plastic (according to customer's requirement) |

| Package Way | Standars Carton+pallet or Customized like Blister all ok |

| LeadTime | 30 days as usual, it will base on the order QTY and delivery due to customer's plan |

| Payment | T/T or L/C |

| MOQ: | 1000PCS |

| Transportation | By sea or By air |

| Equipment | Forging Machine, CNC machine,stamping machine, sand blasting machine etc |

| Customized | Customized are welcome |

| QC Inspection | 100% inspection before package and delivery |

| Factory Experience | More than 20 years manufacture and customized products experience |

| Certificate | ISO9001:2015, ROHS, SGS, Material Certification |

| Sample | Samples and Dimensions report will offer to customer for confirmati |

FAQ

1), Q: How can I get a sample?

A: Yes, if customer want, we will express couple pcs samples free for customer to check before we arrange batch producing, we would like to talk with customer to get your kindly advise .2), Q: How Your Factory Control the Quality ?

A: We control the quality since Material arrive, we have workshop QC responsible for each producting line to check the product dimensions and other details during one by one producing process, inspection QC do spot check for each batch in everyday and package workers do 100% product appearance inspection one by one when they package the parts into the carton. We trust quality need to control on the producing line not final step.3), what's machine you do for these machining parts?

A: we have high precision machining center to produce for small tolerance products and we also have some automatic CNC machine, CNC machine, stamping machine, automatic drill-hole machine and sandblasting maching etc, except the plating, we do whole producing process in own factory.

We are glad to receive your message, Welcome to contact us.

Prev: 230V 304 Pad Water Heating Element Kettle Parts with Good Service Jl

Next: Customized/OEM Stainless Steel Water Electric Kettle Heating Element

Our Contact

Send now